레이저-초음파 검사 방법은 초음파 검사의 감도와 광학 시스템의

유연성을 합한 것으로서 여러

가지 검사에서 유용하게 사용될 수

있다. 이 방법은 금속, 콤포지트 재료, 세라믹 및 액체에서의

검사에

잘 적용된다. 비접촉 방법을 사용하므로 고정된 혹은 움직이는

물체의 굴곡진 부분을

신속하게 검사할 수 있는 장점을 지니고 있다.

이 방법은 열악한 환경이나 기존의 방법으로는

불가능한 높은

온도에서도 검사가 가능하다. 이와 같은 정확성과 유연성은 레이저-초음파

검사가

비파괴 검사 분야에서 매력적인 옵션으로 자리잡게 하고

있다.

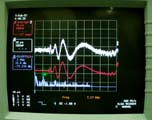

LBU(Laser Based Ultrasound)는 접촉 탐촉자, 스쿼터 탐촉자 혹은 수침용

탐촉자를 사용하는

종래의 초음파 검사 시스템의 원격 검사

방법이라고 할 수 있다. LBU 시스템은 레이저로 물체에

초음파를

발생하게 한 다음 레이저 간섭계(laser interferomete)를 사용하여 물체의

표면 진동을

읽게 된다. 이 과정은 레이저 펄스를 검사하는 부분에

투시하므로 시작된다. 이렇게 하게 되면

그 부분에 초음파가

발생된다. 이 초음파 진동이 물체의 표면에 다다르게 되면 리시버는

표면의

변위를 측정하게 된다.

Applications

The EMF500 receiver allows manufacturers and service companies to investigate a wide

variety of properties, including:

Thickness;

Thickness;

Temperature Temperature

Hardness; Hardness;

Corrosion, grain structure, and porosity; Corrosion, grain structure, and porosity;

Delaminations, cracks, and other defects in solids; Delaminations, cracks, and other defects in solids;

Properties of welds; and Properties of welds; and

Inclusions in molten metal. Inclusions in molten metal.

Attributes

Nondestructive Nondestructive

Noncontact, long standoff distance Noncontact, long standoff distance

High spatial resolution High spatial resolution

Compatible with fiber delivery Compatible with fiber delivery

On-line process monitor capability On-line process monitor capability

Can operate in extreme environments Can operate in extreme environments

Can be scanned rapidly over large, curved surfaces Can be scanned rapidly over large, curved surfaces

Speckle and environmental disturbances can be compressed Speckle and environmental disturbances can be compressed

Benefits

Lower operating costs Lower operating costs

Reduced capital investment Reduced capital investment

Reduced waste and scrap Reduced waste and scrap

Energy savings Energy savings

Higher throughput Higher throughput

100 % certification possible 100 % certification possible

|